Why Aluminum Castings are essential for industrial applications

The Several Uses Light Weight Aluminum Castings: A Comprehensive Overview for Sector Professionals

Aluminum castings play an essential duty across various industries, thanks to their special residential properties. These durable and lightweight parts are vital in vehicle and aerospace applications. Recognizing their benefits and the production processes involved can greatly affect efficiency and performance. As technology developments, new advancements remain to emerge. Sector experts need to think about these elements to make educated choices. The implications of these developments are worth discovering even more.

Benefits of Light Weight Aluminum Castings in Various Industries

Light weight aluminum spreadings offer countless benefits across various industries, making them a favored option for many applications. One of the main benefits is their light-weight nature, which contributes to overall power performance in transport and machinery. This lowered weight additionally boosts convenience of dealing with and setup, causing lower labor expenses.

Additionally, aluminum castings show outstanding deterioration resistance, expanding the life expectancy of elements in extreme settings. Their electric and thermal conductivity permits for efficient warm dissipation and effective electric applications.

In addition, aluminum can be quickly alloyed and adjusted, allowing the creation of complicated forms and designs that satisfy certain design needs. This flexibility sustains innovation in industries such as vehicle, aerospace, and consumer goods.

Lastly, the recyclability of light weight aluminum aligns with lasting methods, making it an eco-friendly option for modern production. On the whole, the benefits of light weight aluminum spreadings position them as necessary products in different markets.

Key Manufacturing Processes for Aluminum Castings

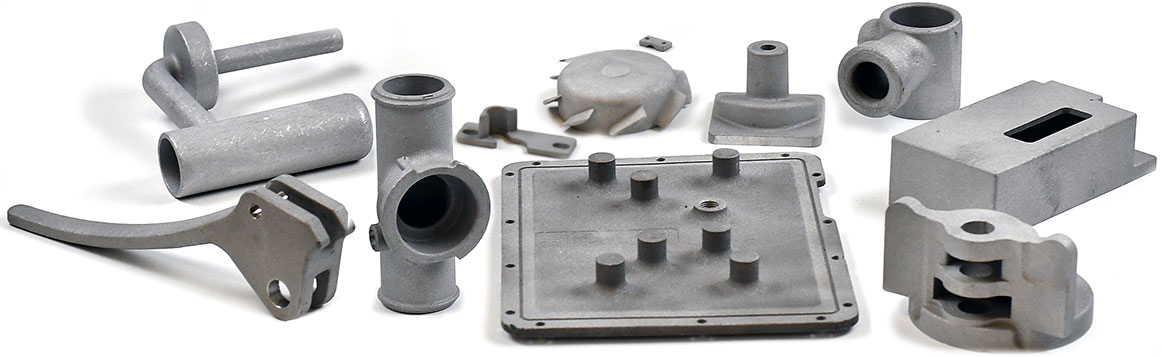

A selection of producing procedures are utilized to create aluminum spreadings, each customized to meet specific application needs and production volumes. Amongst the most typical techniques are sand spreading, die casting, and financial investment spreading.

Investment casting, also referred to as lost-wax spreading, offers exceptional surface coatings and elaborate details, usually utilized for smaller sized, precision parts. Furthermore, gravity casting makes use of the pressure of gravity to fill molds, suitable for bigger castings where accuracy is much less essential. Each process has its advantages, providing to varied commercial requirements while making the most of effectiveness and top quality in light weight aluminum spreading production.

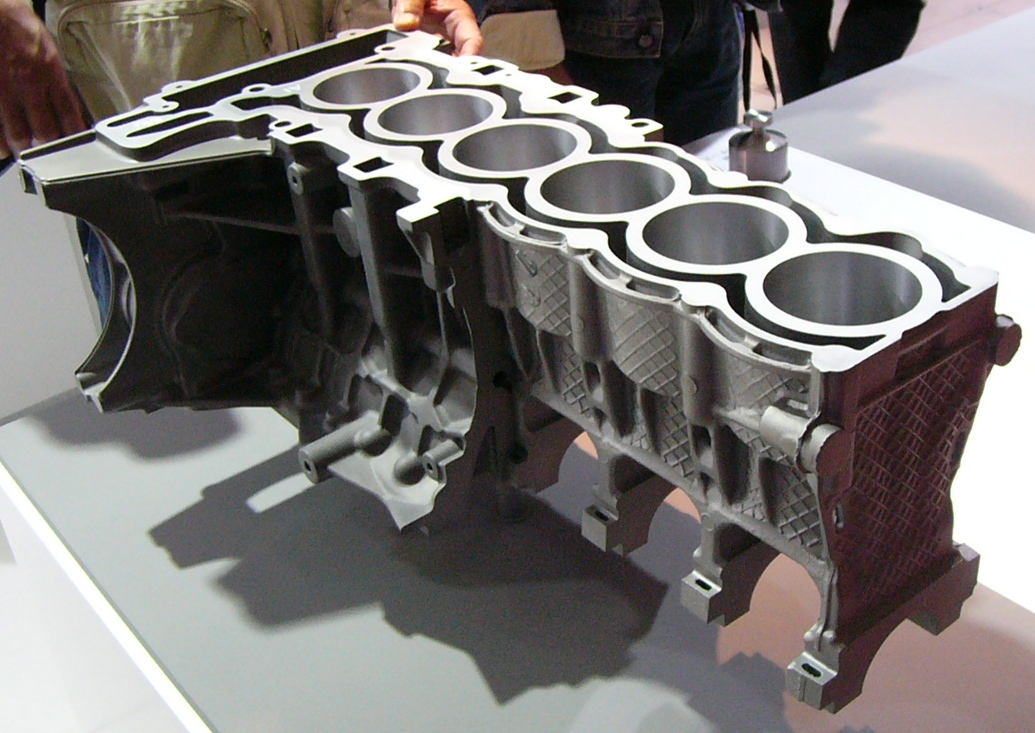

Applications of Aluminum Castings in Automotive and Aerospace

In countless applications within the vehicle and aerospace industries, light weight aluminum castings play an essential function due to their light-weight buildings and exceptional strength-to-weight proportion. In the automotive market, elements such as engine blocks, transmission cases, and wheel edges are frequently produced utilizing light weight aluminum castings. These parts take advantage of reduced weight, causing improved fuel performance and enhanced efficiency.

In aerospace, aluminum spreadings are crucial for structural elements, including airplane frameworks, touchdown gear, and engine real estates. The product's resistance to corrosion and capacity to hold up against heats make it suitable for these demanding applications. Additionally, aluminum castings promote complicated geometries, allowing the style click reference of complex parts that add to total aircraft efficiency.

Advancements and Developments in Aluminum Casting Innovation

As sectors continue to develop, innovations in aluminum casting technology are driving substantial renovations in performance and performance. Advanced strategies such as 3D printing and spreading simulation software application have actually transformed typical techniques, allowing for much more precise styles and minimized waste. These innovations make it possible for manufacturers to develop intricate geometries that were formerly unattainable, enhancing the convenience of light weight aluminum spreadings.

Additionally, the advancement of new alloy compositions and treatment approaches has boosted mechanical properties, making spreadings lighter yet more powerful. Automated procedures are likewise being incorporated, lessening human error and enhancing production rate.

Finest Practices for Using and picking Aluminum Castings

When utilizing and selecting aluminum spreadings, careful consideration of particular standards can greatly influence the end product's performance and durability. Market professionals need to this article examine the specific application requirements, including load-bearing capabilities, rust resistance, and thermal conductivity. Choosing the ideal alloy is important, as various alloys offer differing attributes and toughness.

Additionally, recognizing the spreading process-- whether sand casting, pass away spreading, or investment casting-- will influence the end product's high quality and cost-effectiveness. Quality assurance procedures, such as non-destructive screening and dimensional evaluations, are important to assure that the castings satisfy industry requirements.

Correct handling and storage of light weight aluminum spreadings can avoid damage, ensuring peak efficiency. Working together with reputable distributors that prioritize high quality control can enhance the reliability of the ended up elements. By sticking to these finest techniques, industry professionals can make best use of the benefits of aluminum castings in their applications.

Often Asked Inquiries

What Are the Ecological Effects of Light Weight Aluminum Spreading Manufacturing?

Aluminum casting production can bring about significant environmental effects, including greenhouse gas discharges, energy intake, and source exhaustion. Furthermore, incorrect waste management may lead to dirt and water contamination, influencing neighborhood ecological communities and areas.

Just How Do Aluminum Castings Contrast to Other Steel Spreadings?

Aluminum spreadings are lighter and corrosion-resistant compared to various other steel spreadings like iron or steel. They provide premium thermal and electric conductivity, making them excellent for applications where weight and durability are crucial aspects.

What Is the Cost Distinction Between Aluminum and Other Products?

The cost of aluminum spreadings commonly ranges from modest to high, frequently a lot more affordable than stainless-steel yet costlier than some plastic choices. Aluminum Castings. Variables such as production material, volume, and complexity specs significantly affect general pricing

Can Aluminum Castings Be Reused?

Light weight aluminum spreadings can indeed be recycled. This procedure considerably decreases energy usage and ecological influence contrasted to creating new aluminum, making reusing an important technique in promoting sustainability and source preservation within various industries.

What Safety and security Procedures Should Be Taken Throughout Light Weight Aluminum Casting Processes?

During light weight aluminum casting processes, essential precaution consist of wearing safety equipment, ensuring correct air flow, using heat-resistant devices, maintaining tools, Read More Here and complying with safety methods to avoid exposure to dangerous materials and decrease the danger of crashes. (Aluminum Foundry)

Sand casting involves creating a mold and mildew from sand, enabling for huge spreadings and intricate shapes. Financial investment casting, likewise understood as lost-wax spreading, supplies remarkable surface area finishes and complex details, typically made use of for smaller, accuracy elements. Furthermore, gravity casting utilizes the pressure of gravity to fill up mold and mildews, appropriate for larger spreadings where precision is less essential. Furthermore, comprehending the casting procedure-- whether sand casting, die spreading, or investment spreading-- will certainly affect the final product's high quality and cost-effectiveness. Light weight aluminum spreadings are lighter and corrosion-resistant contrasted to other metal castings like iron or steel.